THE WALKER DIFFERENCE.

WHY ALUMINUM?

Aluminum boats are famously tough and rugged, which makes them ideal for those who require uncompromising strength and reliability. Almost all governmental and commercial operations run aluminum vessels for this reason, especially in the Pacific Northwest with our log-riddled waters.

Despite their durability, aluminum boats are also typically lighter than their fiberglass counterparts. This translates to better performance for the same power and enhanced fuel economy.

Furthermore, aluminum boats are infinitely customizable as they’re each built piece by piece. Unlike a fiberglass boat,which is built in a mold with a fixed layout, any part of an aluminum boat can be changed to suit a client’s preferences. This opens up a world of possibilities for possible layouts and arrangements. This is especially useful when building specialty commercial craft for industries like aquaculture, where operators need specific equipment or features like a well deck.

At Walker, we build boats that stay true to their commercial roots while embracing the styling, comforts and conveniences expected of modern yachts.

IT ALL STARTS WITH DESIGN

Early aluminum boats were known for being pretty bare-bones craft. They would be cut from simple flat patterns with a circular saw, and then massaged into shape with grinders and hammers. As technology progressed, new design methods became available, but many builders remained stubborn and continued to build their boats the “old school way.”

This way can certainly result in a strong hull that comes together quickly, but offers very little flexibility for refining and optimizing hull shapes. Boats built this way tend to pound in chop due to their perfectly developed hull bottoms, which result in a much flatter forward deadrise.

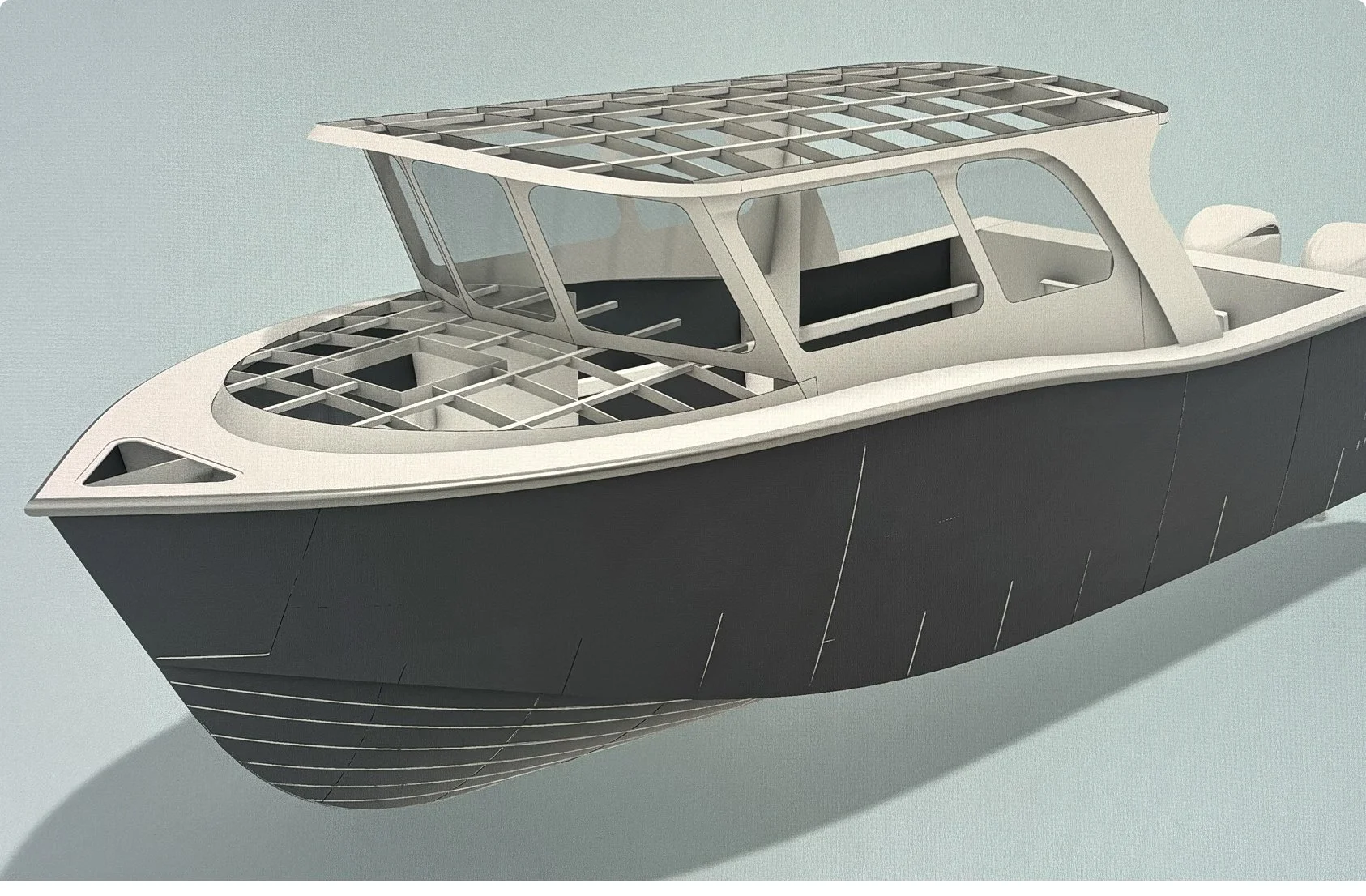

When anyone takes a new Walker Boat for a spin, they are almost always shocked by how smooth and soft the ride is compared to fiberglass and other welded aluminum boats. Our signature ride quality is a direct result of our state of the art CAD design process and CNC cutting capabilities. These tools allow us to refine and dial in hull shapes that are simply not possible to produce off a flat pattern the traditional way.

IS THE JUICE WORTH THE SQUEEZE?

If you are at all familiar with aluminum boat construction, you would expect the hull to be built upside down to start. Most boats are built this way because it’s more convenient to join the plate together and weld out the seams before rotating and inserting the structure. This is only possible with fully developable hull surfaces as there is very little force required to join the plate. This makes an easy-to-build boat, but ultimately sacrifices ride quality.

All Walker boats are built right-side up using a special assembly jig. This beefy steel frame allows us to tease out warped hull shapes that improve the ride and handling while eliminating the pounding that so many aluminum boats are notorious for. While it is certainly harder to build a boat this way, we consider it a crucial step towards delivering the performance our clients have come to expect out of our boats.

The bottom is then reinforced with a heavy-duty blend of interlocking longitudinal stringers and transverse frames. Some may call this overkill, but our aim is to produce the stiffest, quietest, and longest-lasting aluminum hulls possible. No matter the use case, we build all of our boats to a full commercial spec, so they can handle any type of chop you could imagine. Despite their durability, aluminum boats are also typically lighter than their fiberglass counterparts. This translates to better performance for the same power and enhanced fuel economy.

WHAT’S UNDER THE HOOD

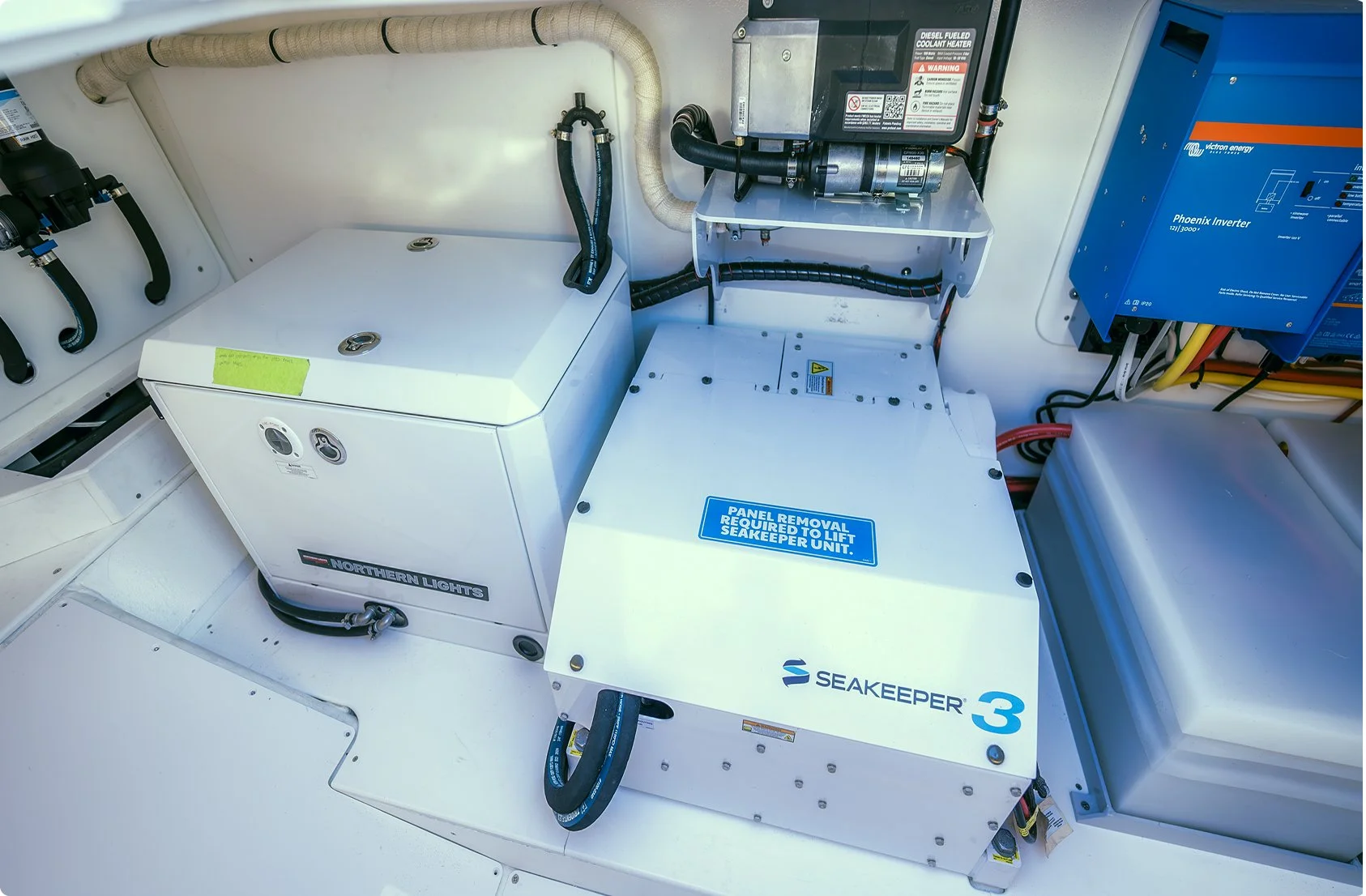

Many production builders try their best to hide their rigging as much as possible. We choose to show ours off proudly as it’s the result of hundreds of hours of hard work performed by our talented technicians.

Staying true to our commercial roots, we also believe that anything that goes into a boat must be able to come out for service. We go to painstaking lengths to ensure that every part, including fuel tanks, can be removed without cutting or altering any structure. This is highly unusual, but pays dividends when the time comes to service the boat. This means far less time in the shop and more out on the water.

In keeping with this spirit, our wiring harnesses are fully labelled by printing directly onto the heat shrink, ensuring maintenance and troubleshooting are as straightforward as possible. We can also configure your boat’s electrical system to include large-capacity lithium battery banks and solar backup charging capability.